I was recently re-reading chapter 11 on the black printer in Yule's Principles of Color Reproduction [1].

When in 1719 Jacob Christoph Le Blon invented the principle of trichromatic printing (British patent 423), one of the innovations was his adding a fourth mezzotint engraving plate for a black separation [2]. The black separation simultaneously solved a number of problems:

- since a gray component is present in a large portion of each image, the black separation can be used as a registration key (therefore the abbreviation K)

- when the gray component is removed from the chromatic layers, these are thinner and therefore use less of the more expensive color inks

- in addition, the drying time is shorter (ink limits) and the press can be run faster, further reducing cost

- the gray balance is improved, more robust, and the blacks are cleaner

- last but not least, the gamut is considerably extended for dark colors

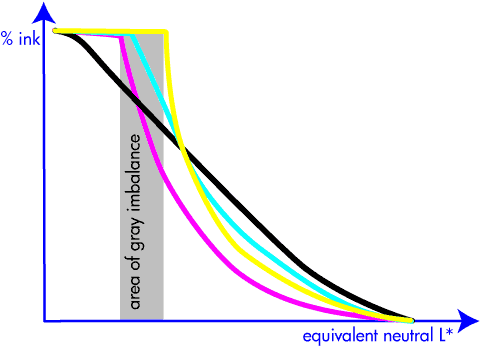

The first step in characterizing (i.e., determining the color transformation for) a color printer is to balance the grays. After this step, we know how much cyan, magenta, and yellow ink we need to print to obtain each gray level. Because yellow ink is lighter than cyan and magenta ink, we achieve a maximum gray level where we use the maximum amount of yellow, when there is still room to add cyan and actually only about half of the magenta ink is used.

The tone range from maximum magenta, cyan, yellow to maximum yellow is called the area of gray imbalance, because no gray can be produced. Adding a black separation, the tone range can be increased to include the area of gray imbalance.

Actually, because the black ink is much darker than even magenta, by going all the way to full black, the tone scale can be considerably extended in the range of dark colors.

First a note on terminology. The gray component of a pixel's color was defined by Yule as the amount of the least predominant ink, i.e., min (C, M, Y). In gray component removal (GCR), this minimum was subtracted from the CMY coordinates and formed the black printer. Making room for black by reducing CMY by any other amount was called undercolor removal (UCR). Today the term UCR is no longer used and the term GCR encompasses both the original GCR and UCR.

The gray component replacement function (or simply black function) is difficult to optimize. Three regions in the tone scale are difficult: the dark colors, the light (right) edge of the area of gray imbalance, and the light colors.

Of the three, the middle tone region at the light edge of the area of gray imbalance is easiest to solve. Indeed, the constraint is that the black function must be smooth, i.e., not start abruptly.

In the dark region, the black function is determined by a trade-off between richness of the blacks, ink limits, and the ink cost. Because the shadows are darkened, their contrast is reduced and consequently the contrast has to be exaggerated in the shadows to preserve shadow detail visibility.

By making the middle region smooth, part of the gray component is removed in the light tone range. Normally the substrate on which we print is white. A lighter tone means that less ink is deposited, which in turns means that more white is added. Adding white to a color desaturates it, therefore an aggressive black function will yield a print lacking saturation [3, 4].

By avoiding black ink in light tones, a larger area of the substrate is covered with ink (hiding white), and because of simultaneous contrast, the perceived color is more vivid. This is somewhat related to a skeleton black ([1] p. 286), where such a black printer is used, but without UCR.

However, avoiding black in light tones introduces a complexity in designing the halftoning algorithm, because the simultaneous contrast also amplifies the perceived color error. Therefore, a poor halftoning algorithm requires more accuracy in the color transformation, while a good halftoning algorithm allows for larger tolerances in the color transformation, as well as in the printer stability.

The above information is purely historical. When Kodak's Yule wrote his book, my PC was an Olivetti P101 with 9 registers of data memory, program memory for 120 instructions, and processing speed limited by the time it took a register's mechanical wave on the memory wire to reach the reading terminal, probably running at a few dozen IPS. When Mik and Dusty wrote their report, my PC was a Dorado, with 4M bytes of memory and 1 MIPS. Today I have an HP xw4600 with 2G bytes and running at about 2000 MIPS.

Because of this incredible increase in performance, on today's computers we can compute a fancy black printer using algorithms based on computational and differential geometry models. While in the past we were limited to colorimetry based on aperture colors for color correction, now we can take spatial (complex) color into consideration. This is why today we get such and exceptional color print quality at such a low cost.

If you wrote or read a good recent paper on this subject, share it as a comment to this post.

- John A.C. Yule, Principles of Color Reproduction, Wiley, New York, 1967

- J.D. Mollon, "The Origins of Modern Color Science", in The Science of Color (Second Edition), Steven K. Shevell editor, Elsevier Science, 2003

- Michael G. Lamming and Warren L. Rhodes, Towards "WYSIWYG" Color, Xerox PARC Technical Report EDL-88-2, P87-00018, April 1988

- Michael G. Lamming and Warren L. Rhodes, "A Simple Method for Improved Color Printing of Monitor Images, ACM Transactions on Graphics, 9, 4, October 1990, 345-375

No comments:

Post a Comment